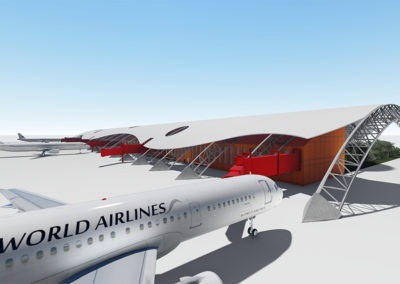

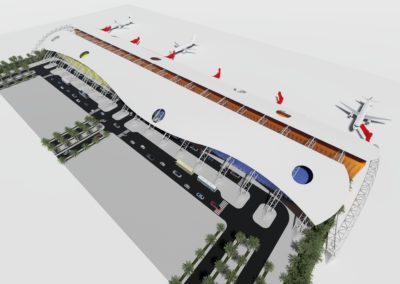

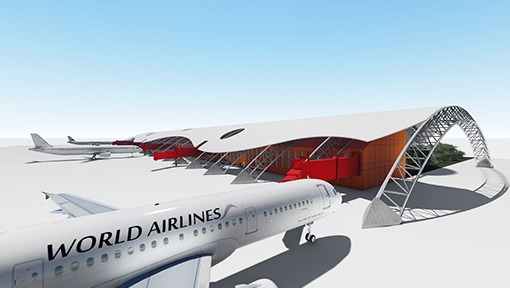

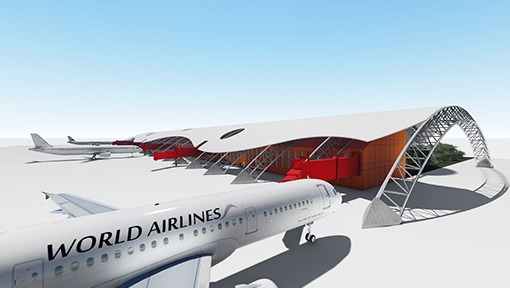

Modular airport terminals

Gaptek offers two base models depending on the type of structure. Every model has different characteristics and options that our engineering department can adjust to develop a solution tailored to your company’s requirements.

The two terminal models are costumized and designed with the Gaptek System and can be tailored to all sorts of needs.

Below is a description of all specifications and options that each model offers.

Characteristics

Terminal FLAT

Technical specifications

Required cementation: Yes

Structure:

- Structure assembly: Mechanical joints

- Material: High resistance alloy aluminum AW-6082-T6

- Warranty: 20 years

Standard Resistances:

- Wind Standard: 140km/h

- Fire Standard: REI30

- Snow Standard: 120kg/m

- Climate conditions: -20 ºC to 55ºC

Envelope:

- Exterior: Rock wool sandwich panel/high-resistance tensile canvas

- Interior: Rock wool sandwich panel

Certifications:

- ISO 9001:2015 in Quality Management System

- UNE-EN ISO 14001 in Environmental Management

- UNE-ISO/IEC 27001 in Information Security Management

- ISO 45001:2018 in Occupational Health and Safety Management System

- CE Marking in all materials, including EN-1090 in relation to steel and aluminum structures

Options

- Hurricane Kit: up to 250 km/h

- Fire Plus: up to REI120

- Snow Plus: up to 3 KN/m2

Additional elements:

- Gaptek modules for shops and offices

- Control tower

- Ground connection

- High efficiency air cooling system

- Additional doors for vehicles and personnel

- Geothermal energy system

Additional services:

- Maintenance

- Life warranty with Gaptek maintenance

- Logistics

Applicable standards:

- International Building Codes

- Eurocodes

- Spanish Technical Building Codes (CTE)

- UFC

Terminal ARCH

Technical specifications

Required foundation: Yes

Structure:

- Structure assembly: Mechanical joints

- Material: High resistance alloy aluminum AW-6082-T6

- Warranty: 20 years

Standard Resistances:

- Wind Standard: 140km/h

- Fire Standard: REI30

- Snow Standard: 120kg/m

- Climate conditions: -20 ºC to 55ºC

Envelope:

- Exterior: Rock wool sandwich panel/high-resistance tensile canvas

- Interior: Rock wool sandwich panel

Certifications:

- ISO 9001:2015 in Quality Management System

- UNE-EN ISO 14001 in Environmental Management

- UNE-ISO/IEC 27001 in Information Security Management

- ISO 45001:2018 in Occupational Health and Safety Management System

- CE Marking in all materials, including EN-1090 in relation to steel and aluminum structures

Options

- Hurricane Kit: up to 250 km/h

- Fire Plus: up to REI120

- Snow Plus: up to 3 KN/m2

Additional elements:

- Gaptek modules for shops and offices

- Control tower

- Ground connection

- High efficiency air cooling system

- Additional doors for vehicles and personnel

- Geothermal energy system

Additional services:

- Maintenance

- Life warranty with Gaptek maintenance

- Logistics

Applicable standards:

- International Building Codes

- Eurocodes

- Spanish Technical Building Codes (CTE)

- UFC

Gaptek is synonymous with trust

Short build time

Pre-design and production of buildings for rapid assembly on site.

Turnkey solutions

Predefined quality

All construction elements can comply with the CE marking and are subjected to the strictest quality controls.

Energy efficiency

We incorporate passive systems for greater energy savings.

Low maintenance

Minimum maintenance of the structures, even in aggressive environments, due to the antioxidant properties of aluminum.

Scalability

Expandable and adaptable buildings to your activity thanks to the use of replicable structures of modular architecture.

FAQs

What structural materials are used by Gaptek?

The advantages of aluminum as structural material as opposed to steel are numerous, such as the optimization and customization of the profiles according to its specific use, as compared with steel’s standard and normalized profiles, the lightness of the profiles and its resistance, the low maintenance thanks to the anticorrosive properties of aluminum and its total recyclability.

What type of machinery is required for the assembly of the modular airport terminals?

Thanks to the lightness of aluminum profiles, the structural materials optimization and the simple assembly of our system using dry joints, it is not required to use very heavy machinery or large cranes to assemble our airport terminals. Only ordinary machinery such as lifting platforms and telescopic cranes.