Aluminum in Construction: More Sustainable and Efficient Structures

Gaptek specializes in developing sustainable construction solutions, always focused on maximizing performance and minimizing the environmental impact of each project. For the company, material selection is crucial, and aluminum has become one of its main allies. Its lightness, strength, and durability make it an ideal choice over steel, especially for constructions requiring transport efficiency, quick assembly, and low maintenance. In this article, Gaptek shares the reasons why it prioritizes aluminum and how its qualities contribute to their mission of delivering innovative and environmentally responsible structures.

In the next article, the company will delve deeper into aluminum’s energy efficiency and carbon footprint, exploring its role in sustainable construction.

1. Lightweight and Transport Efficiency: Aluminum is much lighter than steel, with a density of only 2700 kg/m³ compared to steel’s 7850 kg/m³. This translates to lighter structures that are easier to transport and assemble, significantly reducing logistical and installation costs. Furthermore, the lower weight of aluminum reduces the foundation requirements, further lowering construction costs without compromising structural stability.

2. Strength and Design Flexibility: Aluminum’s lightness does not compromise its strength. Aluminum offers an excellent strength-to-weight ratio, making it suitable for applications where durability and load-bearing capacity are essential. This combination of lightness and strength enables innovative and efficient structural designs, surpassing traditional steel limitations.

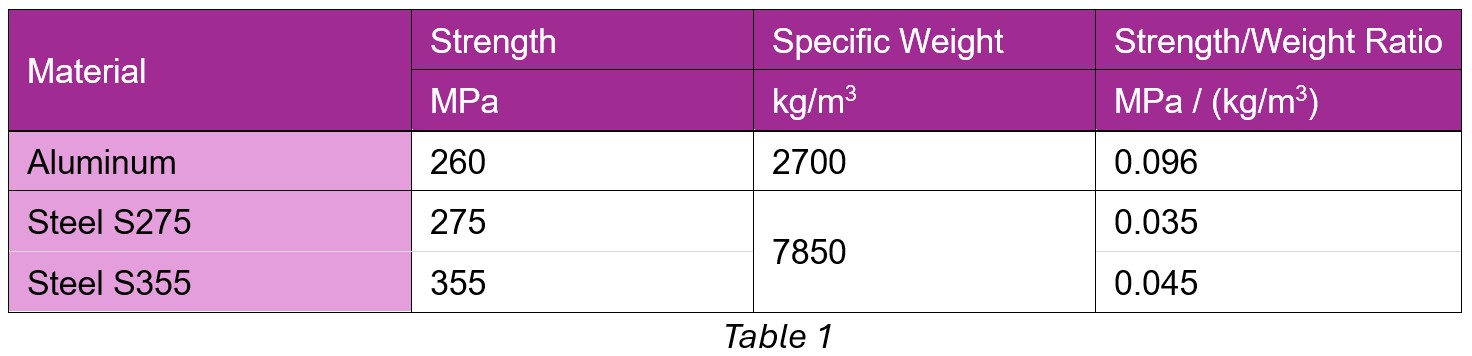

The table 1 shows the values for strength, specific weight, and strength-to-weight ratio of each material. Although aluminum has strength similar to Steel S275 (260 MPa versus 275 MPa), its specific weight is much lower (2700 kg/m³ compared to 7850 kg/m³). This lower weight allows aluminum to achieve a strength-to-weight ratio of 0.096 MPa/kg/m³, significantly higher than both steels: S275 has a ratio of 0.035 MPa/kg/m³, and S355, 0.045 MPa/kg/m³. This indicates that aluminum is far more efficient for applications where reducing weight without compromising strength is essential.

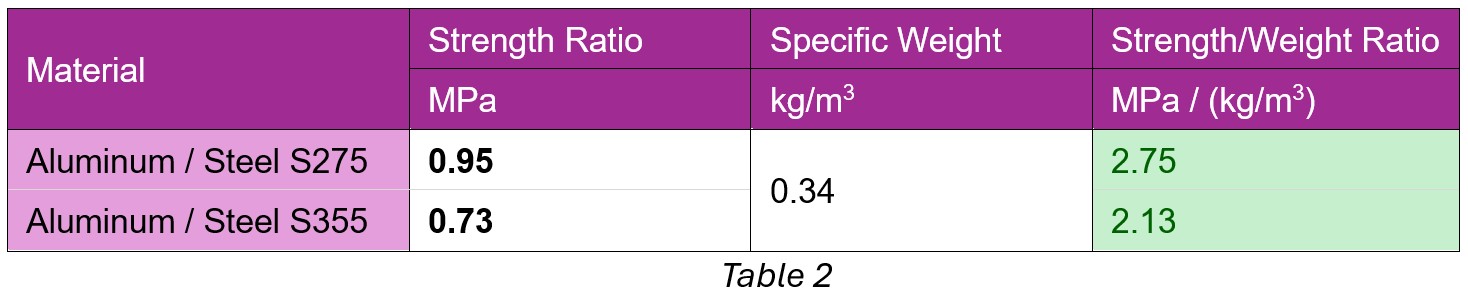

The table 2 presents a direct comparison of aluminum’s strength-to-weight ratio with Steel S275 and S355. We see that, in terms of weight, aluminum is 66% lighter than both types of steel (with a relative weight value of 0.34 compared to 1 in steels). This, combined with its high strength, makes aluminum’s strength-to-weight ratio 2.75 times greater than Steel S275 and 2.13 times greater than Steel S355.

3.Quick and Safe Assembly: Construction with aluminum often does not require welding. Instead, aluminum is assembled using bolted joints, making the assembly process faster, safer, and more cost-effective. This method also reduces the risk of joint tension loss—a critical problem in steel assemblies that can lead to deformations or even structural collapse.

4.Durability and Corrosion Resistance: Aluminum stands out for its natural corrosion resistance, offering a significant advantage over steel, which often requires additional protective treatments, such as galvanization or painting. These coatings involve constant maintenance costs, specialized personnel, and considerable environmental impact due to the chemical compounds used. With aluminum, these treatments are unnecessary, contributing to greater durability and reduced maintenance costs in the long term, while also minimizing environmental impact.

In conclusion, aluminum is an extremely efficient and versatile material for construction, distinguished by its lightness, strength, and durability. Its low weight significantly reduces transport costs and enables more innovative structural designs without compromising stability or load-bearing capacity.

Additionally, its excellent strength-to-weight ratio makes it ideal for applications requiring light yet strong structures. Aluminum also offers significant advantages in terms of assembly and maintenance: its ease of bolt-assembly and natural corrosion resistance minimize long-term costs and environmental impact.

Together, these characteristics make aluminum a preferred alternative for construction projects aimed at optimizing resources, reducing emissions, and maintaining high standards of durability and sustainability.

Content owned by Gaptek.

Layout by the Gaptek Marketing Department.

Copyright 2024.

solutions

- Hangars

- Military bases

- Warehouses

- Shelters