Modular hospitals

The solution you need, whenever and wherever you need it.

Our vision

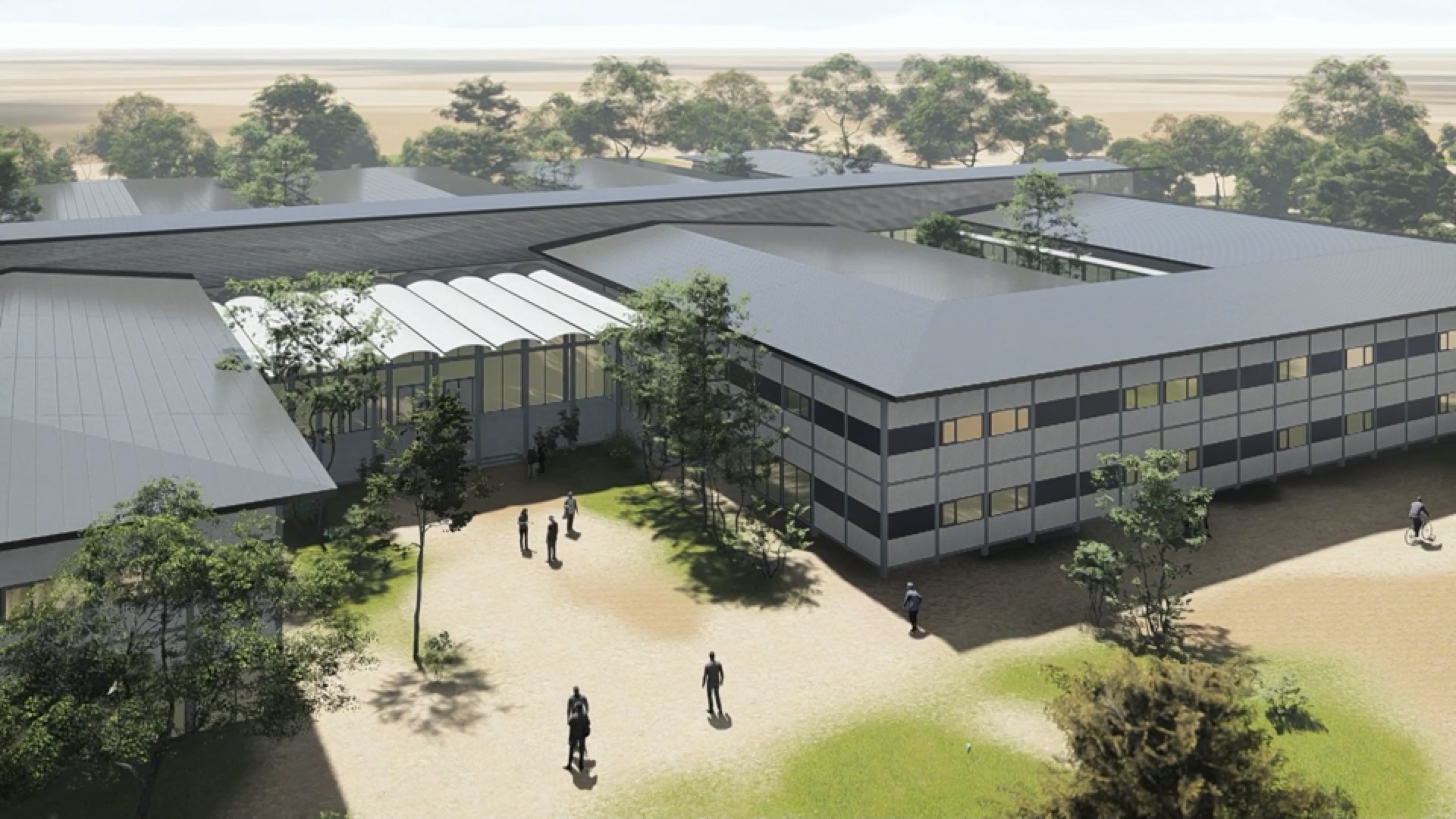

Gaptek provides the required infrastructures to offer high-quality medical assistance and in decent conditions around the world

Our simplified constructive system covers the medical needs through highly qualified medical centers. They are designed to give a professional medical assistance everywhere in the world.

The concept of prefabricated hospital is entirely created to offer an on-terrain humanitarian solution. It consists of prefabricated modules that are designed to withstand any type of climate and adaptable to every terrain thanks to its adjustable legs.

The materials are light and resistant to the chemical substances that are normally used in medical activities.

The assembly is simple and can be done autonomously using a construction handbook and with Gaptek’s supervision, after the team leaders have received the required training by Gaptek.

The solution offered by Gaptek is the design and supply of a hospital building for health infrastructures to respond to the COVID-19 crisis.

The system offered raises the possibility of adapting each hospital to the specific needs in each case, by combining the modules.

Characteristics

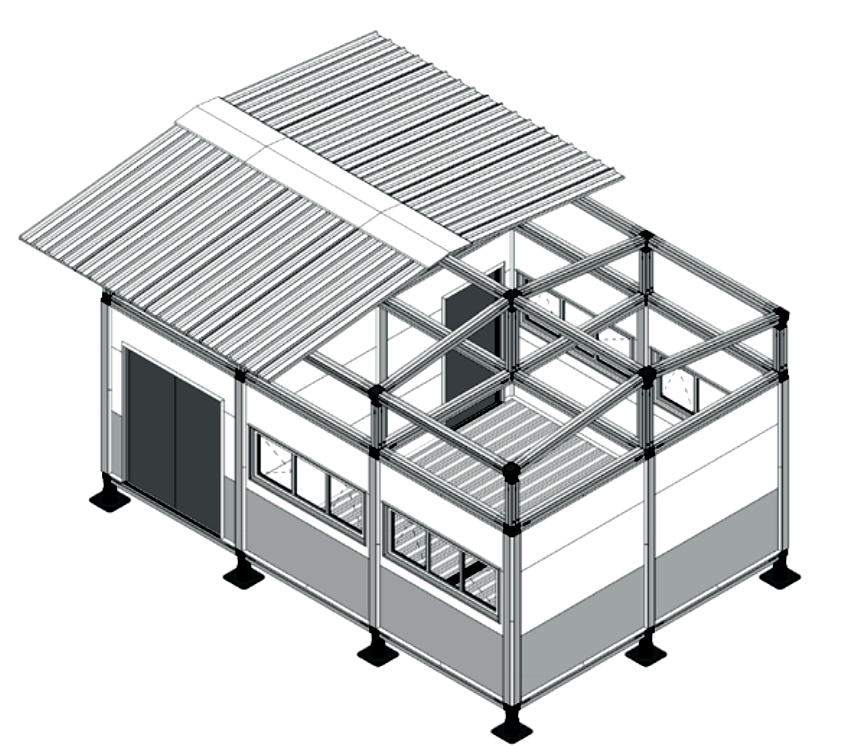

Module Field +

Technical specifications

Dimensions: Modules of minimum 2,40m x 2,40m with unlimited longitudinal scalability

Assembly time: Depending on dimensions

Construction System: Gaptek Modular

Required cementation: No

Structure:

- Structure assembly: Mechanical joints

- Material: High resistance alloy aluminum AW-6082-T6

- Warranty: 20 years

Standard Resistances:

- Wind Standard: 120 km/h

- Fire Standard: REI30

- Snow Standard: 0.5 KN/sqm

- Climate conditions: -20 ºC to 55ºC

- Earthquake Standard: 0.1 g

Envelope: Insulating panel

Certifications:

- ISO 9001:2015 in Quality Management System

- UNE-EN ISO 14001 in Environmental Management

- UNE-ISO/IEC 27001 in Information Security Management

- ISO 45001:2018 in Occupational Health and Safety Management System

- CE Marking in all materials, including EN-1090 in relation to steel and aluminum structures

Options

Assembly:

- In charge of Gaptek

- Autonomous method: Training and supervision offered to the client

- On site

- On Gaptek facilities

Distribution options:

- Medical consultations

- Waiting room

- Operating rooms

- X-rays

- Warehouses

- Other uses: dressing room, dining room, office, toilets, etc.

Resistances Plus:

- Hurricane Kit: up to 250 km/h

- Fire Plus: up to REI120

- Snow Plus: up to 2 KN/sqm

Additional elements:

- Aggregation of multiple modules to create complex

- Adjustable height legs

- Interconnection systems between modules: platforms, stairs…

- Ground connection

- High efficiency air cooling system

- Assembly tools (autonomous assembly method)

- Ballistic protection

Additional services:

- Maintenance

- Logistics and storage

- Lifetime warranty with Gaptek maintenance

- Foundation on lands that require it

Applicable standards:

- International Building Codes

- Eurocodes

- Spanish Technical Building Codes (CTE)

- UFC

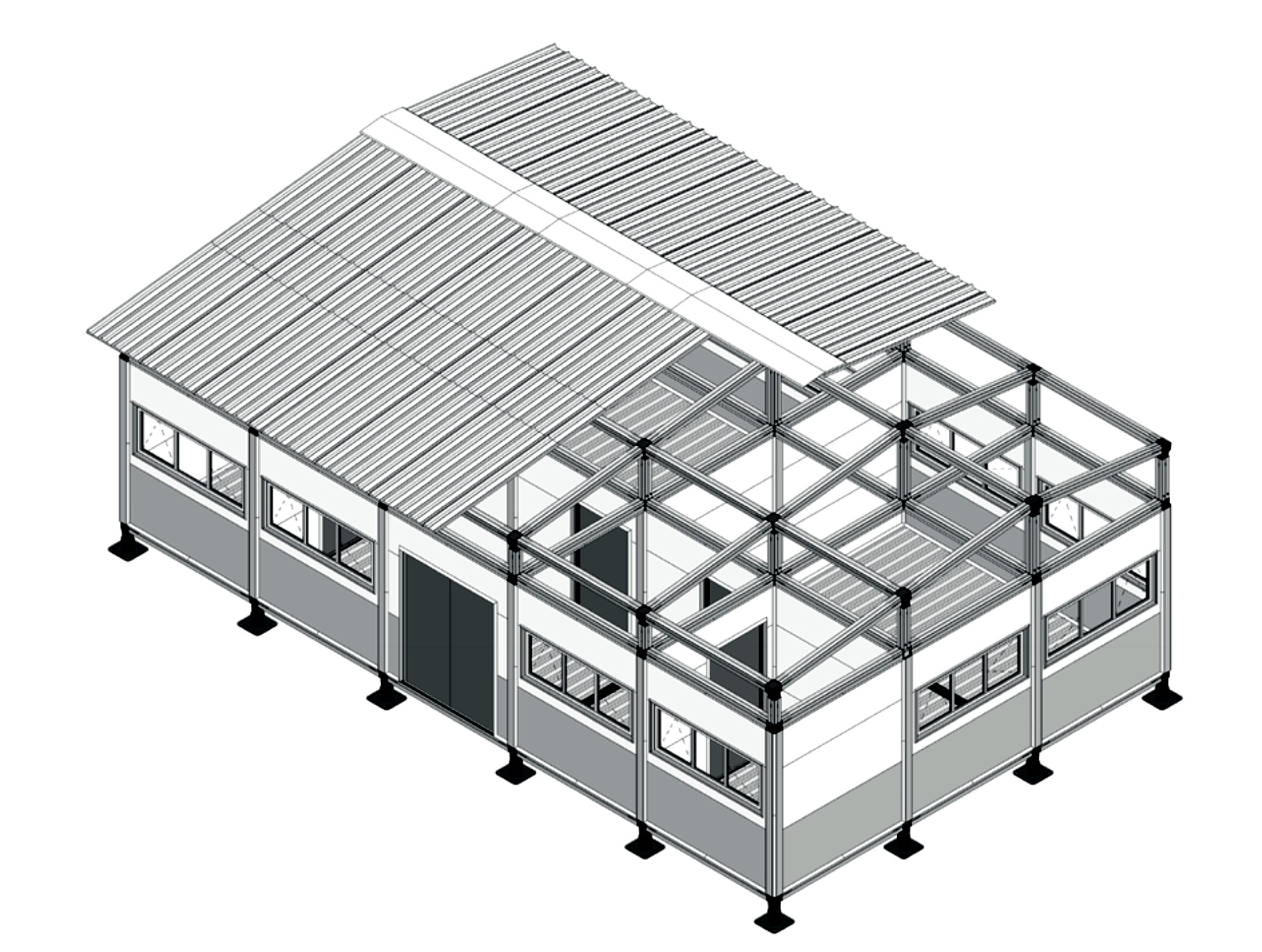

Module Performance

Technical specifications

Dimensions: Modules of minimum 2,40m x 2,40m with unlimited longitudinal scalability

Assembly time: Depending on dimensions

Construction System: Gaptek Modular

Required cementation: No

Structure:

- Structure assembly: Mechanical joints

- Material: High resistance alloy aluminum AW-6082-T6

- Warranty: 20 years

Standard Resistances:

- Wind Standard: 120 km/h

- Fire Standard: REI30

- Snow Standard: 0.5 KN/sqm

- Climate conditions: -20 ºC to 55ºC

- Earthquake Standard: 0.1 g

Envelope: Insulating panel

Certifications:

- ISO 9001:2015 in Quality Management System

- UNE-EN ISO 14001 in Environmental Management

- UNE-ISO/IEC 27001 in Information Security Management

- ISO 45001:2018 in Occupational Health and Safety Management System

- CE Marking in all materials, including EN-1090 in relation to steel and aluminum structures

Options

Assembly:

- In charge of Gaptek

- Autonomous method: Training and supervision offered to the client

- On site

- On Gaptek facilities

Distribution options:

- Medical consultations

- Waiting room

- Operating rooms

- X-rays

- Warehouses

- Other uses: dressing room, dining room, office, toilets, etc.

Resistances Plus:

- Hurricane Kit: up to 250 km/h

- Fire Plus: up to REI120

- Snow Plus: up to 2 KN/sqm

Additional elements:

- Aggregation of multiple modules to create complex

- Adjustable height legs

- Interconnection systems between modules: platforms, stairs…

- Ground connection

- High efficiency air cooling system

- Assembly tools (autonomous assembly method)

- Ballistic protection

Additional services:

- Maintenance

- Logistics and storage

- Lifetime warranty with Gaptek maintenance

- Foundation on lands that require it

Applicable standards:

- International Building Codes

- Eurocodes

- Spanish Technical Building Codes (CTE)

- UFC

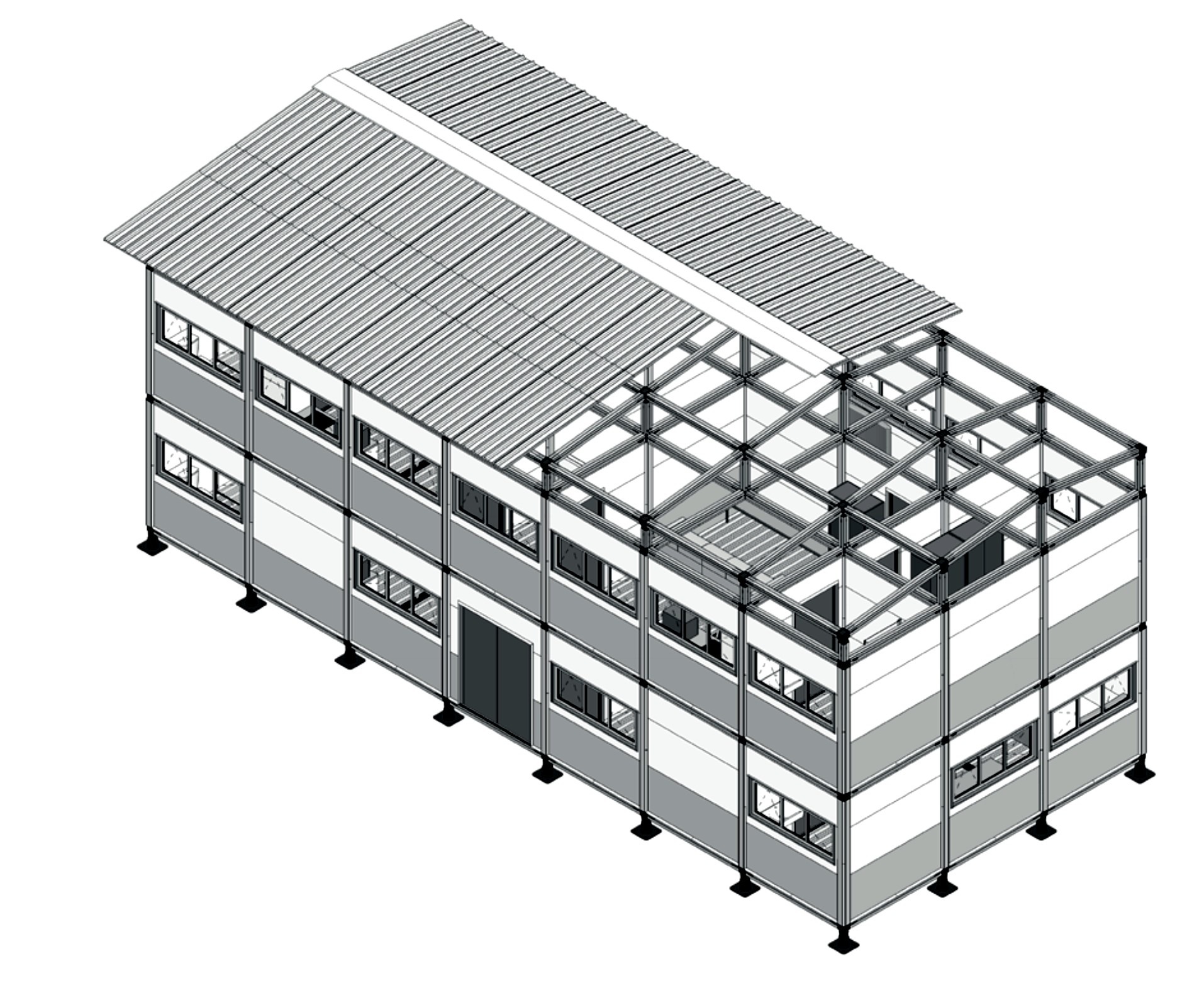

Module Performance DS

Technical specifications

Dimensions: Modules of minimum 2,40m x 2,40m with unlimited longitudinal scalability and up to 3 floors

Assembly time: Depending on dimensions

Construction System: Gaptek Modular

Required cementation: No (recommended)

Structure:

- Structure assembly: Mechanical joints

- Material: High resistance alloy aluminum AW-6082-T6

- Warranty: 20 years

Standard Resistances:

- Wind Standard: 120 km/h

- Fire Standard: REI30

- Snow Standard: 0.5 KN/sqm

- Climate conditions: -20 ºC to 55ºC

- Earthquake Standard: 0.1 g

Envelope: Insulating panel

Certifications:

- ISO 9001:2015 in Quality Management System

- UNE-EN ISO 14001 in Environmental Management

- UNE-ISO/IEC 27001 in Information Security Management

- ISO 45001:2018 in Occupational Health and Safety Management System

- CE Marking in all materials, including EN-1090 in relation to steel and aluminum structures

Options

Assembly:

- In charge of Gaptek

- Autonomous method: Training and supervision offered to the client

- On site

- On Gaptek facilities

Distribution options:

- Medical consultations

- Waiting room

- Operating rooms

- X-rays

- Warehouses

- Other uses: dressing room, dining room, office, toilets, etc.

Resistances Plus:

- Hurricane Kit: up to 250 km/h

- Fire Plus: up to REI120

- Snow Plus: up to 2 KN/sqm

Additional elements:

- Aggregation of multiple modules to create complex

- Adjustable height legs

- Interconnection systems between modules: platforms, stairs…

- Ground connection

- High efficiency air cooling system

- Assembly tools (autonomous assembly method)

- Ballistic protection

Additional services:

- Maintenance

- Logistics and storage

- Lifetime warranty with Gaptek maintenance

- Foundation on lands that require it

Applicable standards:

- International Building Codes

- Eurocodes

- Spanish Technical Building Codes (CTE)

- UFC

Gaptek is synonymous with trust

Short build time

Pre-design and production of buildings for rapid assembly on site.

Turnkey solutions

We offer turnkey solutions, from design, construction, adaptation to building maintenance.

Predefined quality

All construction elements can comply with the CE marking and are subjected to the strictest quality controls.

Energy efficiency

We incorporate passive systems for greater energy savings.

Low maintenance

Minimum maintenance of the structures, even in aggressive environments, due to the antioxidant properties of aluminum.

Scalability

Expandable and adaptable buildings to your activity thanks to the use of replicable structures of modular architecture.

FAQs

What structural materials are used by Gaptek?

The advantages of aluminum as structural material as opposed to steel are numerous, such as the optimization and customization of the profiles according to its specific use, as compared with steel’s standard and normalized profiles, the lightness of the profiles and its resistance, the low maintenance thanks to the anticorrosive properties of aluminum and its total recyclability.

What type of machinery is required for the assembly of the modular hospitals?

Thanks to the lightness of aluminum profiles, the structural materials optimization and the simple assembly of our system using dry joints, it is not required to use very heavy machinery or large cranes to assemble our modules. Only ordinary tools are required to assemble the prefabricated hospitals.

What is Gaptek modular hospitals fire resistance?

The structures of the prefabricated hospitals are protected against fire using inner lining of rock wool sandwich panels. Therefore, the degree of fire resistance will depend on the thickness of the panel and its own fire resistance, adapting the project to the specific regulation and the requirements of the hospitals, without limits.

What is the durability of Gaptek modular hospitals?

The materials used in Gaptek hospitals, as well as in the rest of Gaptek products, have a great resistance and durability, similar to traditional construction systems. Gaptek offers a 20 year guarantee according to the structure and 5 years to the rest of the elements that compose the modules.

I want my prefabricated hospitals to be energy efficient. Is it possible?

Yes. In fact, all Gaptek solutions minimize in a passive way the intervention of machines to reach comfort and energy efficiency. In addition, our system is totally compatible with the installation of renewable energies such as solar panels and geothermal in the prefabricated hospitals.

Are Gaptek modular hospitals resistant to extreme weather conditions?

Yes. Our prefabricated hospitals are designed to withstand the conditions of the places inhabited by 85% of the world’s population, but they can also be designed for the most extreme climates of the planet. An example is the Gaptek warehouse that was built in Antarctica.

Contact form

We make reality your project

Know our capabilities. We invite you to see our corporate video. Do not hesitate to contact us, we will be proud to help you make your project come true.