Hangars

Our solutions in military hangars can accommodate any type of aircraft, from drones to the largest military aircraft in the world.

Our vision

Our Solutions

Permanent Hangars

The permanent hangars are the ideal solution to develop MRO activities due to their characteristics: they comply with the technical codes like any traditional building, but they have a reduced assembly time and a greater adaptability to any context.

Semi-permanent Hangars

The semi-permanent hangars also comply with the technical codes as any traditional building, but their materials allow a greater degree of disassembly and the reuse of approximately 80% of the materials used in the first assembly.

Deployable hangars

They are the solutions with the shortest assembly time and, in addition, they are 100% demountable and relocatable. All the materials can be reused, both structure and envelope, in the next assembly of the building.

Characteristics

Hangar FLAT

Technical specifications

Dimensions: Unlimited

Assembly time: 3 months (civil work) + 3 months (assembly)

Construction system: Gaptek Flat

Required cementation: Yes

Uses:

- Storage

- Executive aviation

- Hangar assembly

- MRO

- Painting

Structure:

- Structure assembly: Mechanical joints

- Material: High resistance alloy aluminum AW-6082-T6

- Warranty: 20 years

Standard Resistances:

- Wind Standard: 120 km/h

- Fire Standard: REI30

- Snow Standard: 0.75 KN/sqm

- Climate conditions: -20 ºC to 55ºC

- Earthquake Standard: 0.1 g

Envelope:

- Exterior: Corrugated metal sheet, high-resistance tensile canvas or panel insulation

- Interior: Rock wool sandwich panel

Certifications:

- ISO 9001:2015 in Quality Management System

- UNE-EN ISO 14001 in Environmental Management

- UNE-ISO/IEC 27001 in Information Security Management

- ISO 45001:2018 in Occupational Health and Safety Management System

- CE Marking in all materials, including EN-1090 in relation to steel and aluminum structures

Options

Plus Resistances:

- Hurricane Kit: up to 250 km/h

- Fire Plus: up to REI120

- Snow Plus: up to 3 KN/sqm

Hangar door:

- Sectional

- Sliding

Additional elements:

- Bridge crane

- Gaptek modules for workshops and offices

- PIT connectors

- Controlled atmosphere

- High efficiency air cooling system

- Additional doors for vehicles and staff

- Geothermal energy system

- Clearance lights

- Sprinklers

Additional services:

- Maintenance

- Life warranty with Gaptek maintenance

- Logistics

Applicable standards:

- International Building Codes

- Eurocodes

- Spanish Technical Building Codes (CTE)

- UFC

- NFPA

- RSCIEI

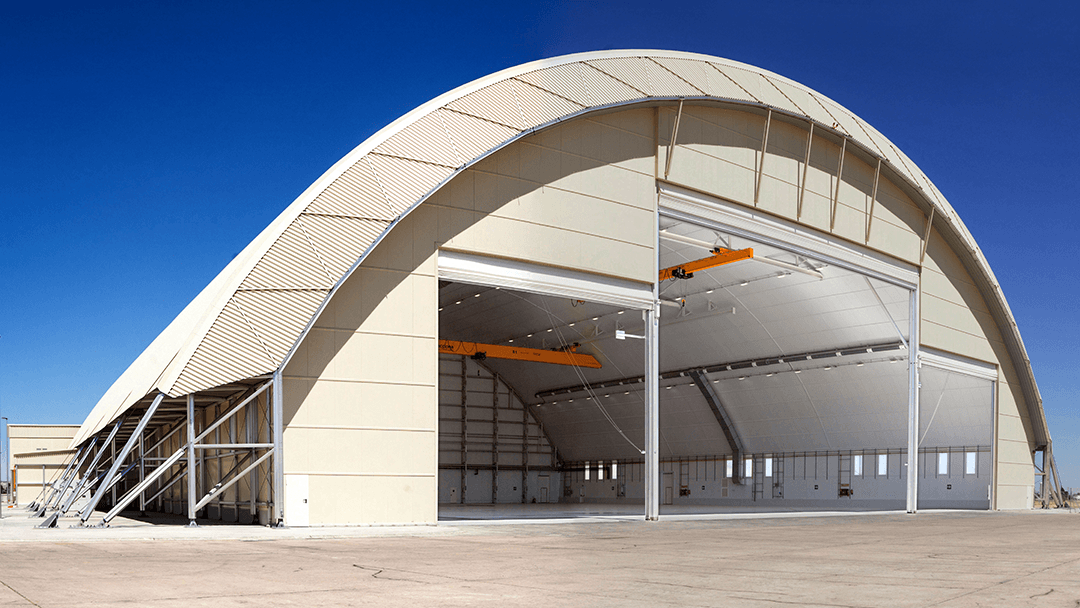

Hangar ARCH

Technical specifications

Dimensions: Unlimited

Assembly time: 3 months (civil work) + 3 months (assembly)

Construction system: Gaptek Arch

Required cementation: Yes

Uses:

- Storage

- Executive aviation

- Hangar assembly

- MRO

- Painting

Structure:

- Structure assembly: Mechanical joints

- Material: High resistance alloy aluminum AW-6082-T6

- Warranty: 20 years

Standard Resistances:

- Wind Standard: 120 km/h

- Fire Standard: REI30

- Snow Standard: 0.75 KN/sqm

- Climate conditions: -20 ºC to 55ºC

- Earthquake Standard: 0.1 g

Envelope:

- Exterior: Corrugated metal sheet, high-resistance tensile canvas or panel insulation

- Interior: Rock wool sandwich panel

Certifications:

- ISO 9001:2015 in Quality Management System

- UNE-EN ISO 14001 in Environmental Management

- UNE-ISO/IEC 27001 in Information Security Management

- ISO 45001:2018 in Occupational Health and Safety Management System

- CE Marking in all materials, including EN-1090 in relation to steel and aluminum structures

Options

Plus Resistances:

- Hurricane Kit: up to 250 km/h

- Fire Plus: up to REI120

- Snow Plus: up to 3 KN/sqm

Hangar door:

- Sectional

- Sliding

Additional elements:

- Bridge crane

- Gaptek modules for workshops and offices

- PIT connectors

- Controlled atmosphere

- High efficiency air cooling system

- Additional doors for vehicles and staff

- Geothermal energy system

- Clearance lights

- Sprinklers

Additional services:

- Maintenance

- Life warranty with Gaptek maintenance

- Logistics

Applicable standards:

- International Building Codes

- Eurocodes

- Spanish Technical Building Codes (CTE)

- UFC

- NFPA

- RSCIEI

Gaptek is synonymous with trust

Short build time

Pre-design and production of buildings for rapid assembly on site.

Turnkey solutions

We offer turnkey solutions, from design, construction, adaptation to building maintenance.

Predefined quality

All construction elements can comply with the CE marking and are subjected to the strictest quality controls.

Energy efficiency

We incorporate passive systems for greater energy savings.

Low maintenance

Minimum maintenance of the structures, even in aggressive environments, due to the antioxidant properties of aluminum.

Scalability

Expandable and adaptable buildings to your activity thanks to the use of replicable structures of modular architecture.

FAQs

What structural materials are used by Gaptek?

Gaptek has developed a construction system based on prefabricated profiles and dry joints, using aluminum as the structural material for the advantages it has as opposed to traditional construction and its great adaptability.

The advantages of aluminum as structural material as opposed to steel are numerous, such as the optimization and customization of the profiles according to its specific use, as compared with steel’s standard and normalized profiles, the lightness of the profiles and its resistance, the low maintenance thanks to the anticorrosive properties of aluminum and its total recyclability.

What type of machinery is required for the assembly of the MRO hangars?

Thanks to the lightness of aluminum profiles, the structural materials optimization and the simple assembly of our system using dry joints, it is not required to use very heavy machinery or large cranes to assemble our hangars. Only ordinary machinery such as lifting platforms and telescopic cranes.

What is Gaptek’s hangars fire resistance?

The structures of the hangars are protected against fire using inner lining of rock wool sandwich panels. Therefore, the degree of fire resistance will depend on the thickness of the panel and its own fire resistance, adapting the project to the specific regulation and the requirements of the hangar, without limits.

What is the durability of Gaptek MRO hangars?

The materials used in Gaptek hangars, as well as in the rest of Gaptek products, have a great resistance and durability, similar to traditional construction systems. Gaptek offers a 20 year guarantee according to the structure and 5 years to the rest of the elements that compose the hangar.

I want my hangar to be energy efficient. Is it possible?

Yes. In fact, all Gaptek solutions minimize in a passive way the intervention of machines to reach comfort and energy efficiency. In addition, our system is totally compatible with the installation of renewable energies such as solar panels and geothermal.

Are Gaptek hangars resistant to extreme weather conditions?

Gaptek buildings are designed to withstand the conditions of the places inhabited by 85% of the world’s population, but they can also be designed for the most extreme climates of the planet. An example is the Gaptek warehouse that was built in Antarctica.

Tell us what aircraft you have and we will tell you what hangar you need.

We make reality your project

Know our capabilities. We invite you to see our corporate video. Do not hesitate to contact us, we will be proud to help you make your project come true.